Rolls are 144 inches that can be cut to any length needed.

Smaller cut quantities are available, contact us today!

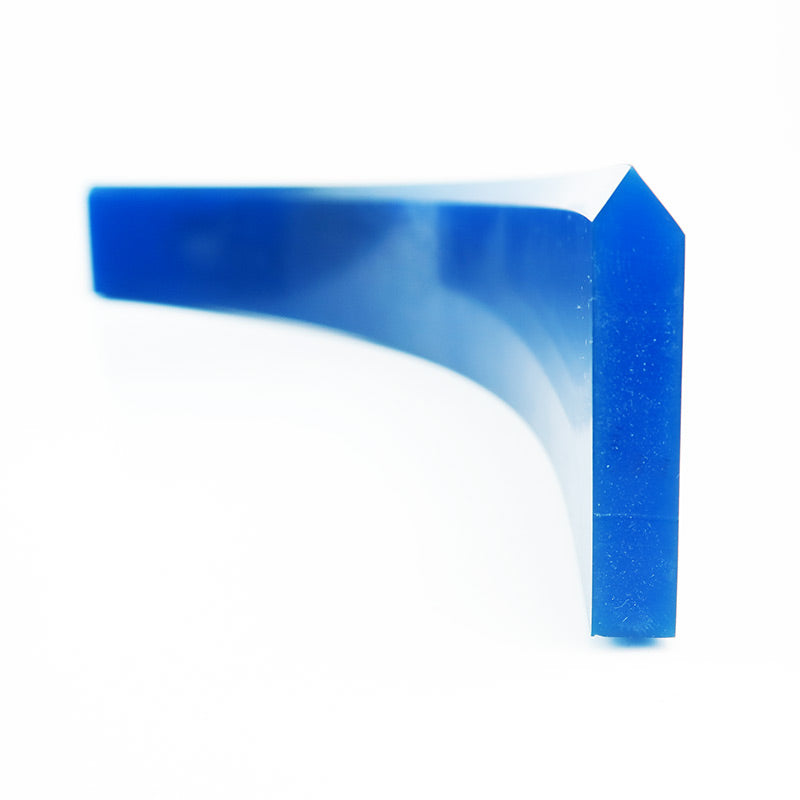

Our polyurethane screen printing squeegees are custom formulated to achieve high solvent resistance and excellent abrasion resistance. This combination results in a squeegee blade that will better maintain its durometer when subjected to aggressive inks and solvents, show minimal swelling during the print run, and retain its sharp edge longer. This will allow for continued quality during the screen print run, thereby increasing productivity.

Which durometer should you use?

60 Durometer - For very thin in, water based inks, and minimal ink deposit, use our softer 60 durometer blade.

70 Durometer - For general purpose use our popular and versatile 70 durometer blade.

80/90 Durometer - For thick, opaque inks and heavier ink deposit, use our stronger 80 or 90 durometer blade.

Maintenance

When printing, monitor production time and rotate squeegees frequently. The necessary rotation frequency is dependent on the ink/solvent system involved in the application. By doing so, you will achieve a more uniform print quality and increase the life of your squeegees. A squeegee should always be wiped clean and dry following its removal from the press and stored flat in a dry environment at room temperature. The blade should be allowed to recover from the ink and solvent attack and rest for a period of 24 hours. It can then be placed back into production, or if necessary re-sharpened and placed back into production.

Storage

Polyurethane Squeegees should always be stored flat in a dry (50% relative humidity) environment at room temperature (approximately 60-70°F). Storage at temperatures below 60°F may show an increase in durometer. This increase has no influence on the physical properties or the performance of the polyurethane. Under these storage conditions, the shelf life of the squeegee is approximately one year. Older squeegees often show increased printing performance.

* Images are for reference only, actual product may vary.

Rolls are 144 inches that can be cut to any length needed.

Smaller cut quantities are available, contact us today!

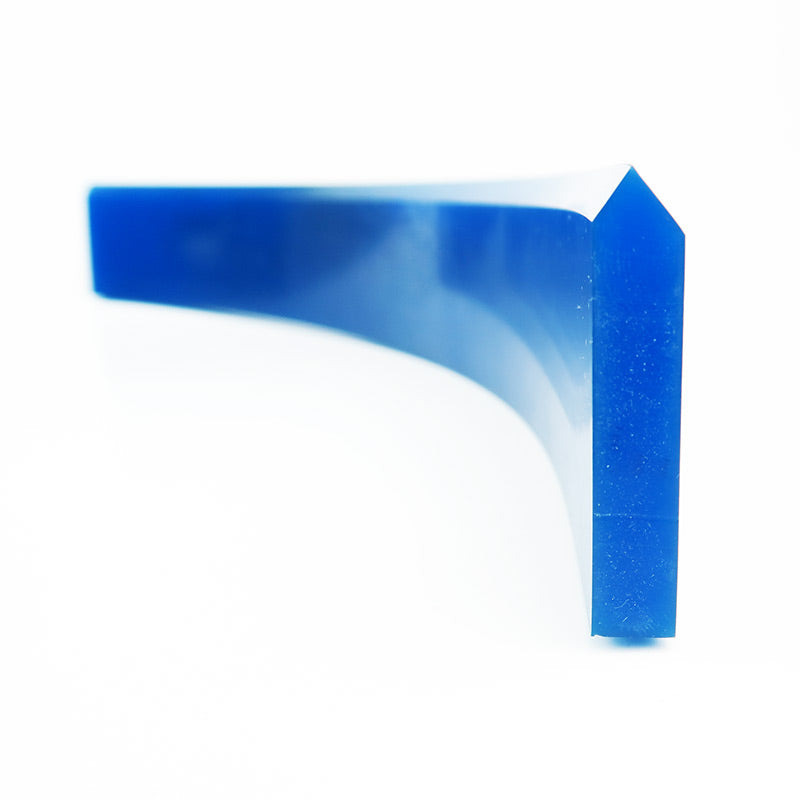

Our polyurethane screen printing squeegees are custom formulated to achieve high solvent resistance and excellent abrasion resistance. This combination results in a squeegee blade that will better maintain its durometer when subjected to aggressive inks and solvents, show minimal swelling during the print run, and retain its sharp edge longer. This will allow for continued quality during the screen print run, thereby increasing productivity.

Which durometer should you use?

60 Durometer - For very thin in, water based inks, and minimal ink deposit, use our softer 60 durometer blade.

70 Durometer - For general purpose use our popular and versatile 70 durometer blade.

80/90 Durometer - For thick, opaque inks and heavier ink deposit, use our stronger 80 or 90 durometer blade.

Maintenance

When printing, monitor production time and rotate squeegees frequently. The necessary rotation frequency is dependent on the ink/solvent system involved in the application. By doing so, you will achieve a more uniform print quality and increase the life of your squeegees. A squeegee should always be wiped clean and dry following its removal from the press and stored flat in a dry environment at room temperature. The blade should be allowed to recover from the ink and solvent attack and rest for a period of 24 hours. It can then be placed back into production, or if necessary re-sharpened and placed back into production.

Storage

Polyurethane Squeegees should always be stored flat in a dry (50% relative humidity) environment at room temperature (approximately 60-70°F). Storage at temperatures below 60°F may show an increase in durometer. This increase has no influence on the physical properties or the performance of the polyurethane. Under these storage conditions, the shelf life of the squeegee is approximately one year. Older squeegees often show increased printing performance.

* Images are for reference only, actual product may vary.

![Ultimate Clean-Up Cards [Box of 1,500]](http://www.pressdoctor.com/cdn/shop/products/SP-NL-SCC500-2_{width}x.jpg?v=1659455977)